Choosing the Best CNC Router Plans

If you are looking for a set of CNC Router Plans so that you can build your own machine, but you have a lot of questions or aren’t sure which one is right for you, then read on. This article will discuss what to expect when buying a set of plans, and what you should consider as you are evaluating which machine is best for you.

If you are in a hurry and just want to see the options and my top picks, here are 9 CNC Router Plans you can build yourself.

Let’s get started by taking a look at the top considerations for choosing which CNC Router Plans you should build from. These points are listed roughly in order of importance.

What is Your Budget?

For most people, the best place to start is your budget. We’re not talking about the how much the set of plans will cost (it varies from free to $200), but how much the completed machine will cost.

The cost to have a working machine can be hard to determine since many plans allow for customization by the builder. For example if you opt for a spindle and VFD over a router, that could be a $200 difference. The same goes for stepper motors and drivers, a PC to run the machine, and software can vary from free to hundreds or even thousands of dollars. When trying to figure out what your final cost will be, pay attention to what is included in the estimates that are published by each manufacturer. Be aware that many do not include the router or spindle, the computer and software needed to run the machine, or even the electronics that are part of the machine.

So, what does it cost to build a CNC router from plans? You can see my estimates for each of the 9 machines listed in the article linked above. They range from about $700 to $5000 and up. If you have a strict budget, this may quickly narrow the field of which models you need to compare.

When thinking about your budget, consider that in addition to the machine, once you get running you can easily spend a couple hundred to over a thousand dollars on router bits or end mills and optional accessories (clamps, dust collection, tool probe, edge finder, vise, add-on laser or drag knife, compressor, coolant mister, vacuum hold downs, the list goes on).

What Do You Want to Make?

That is the next question you should be asking yourself before deciding which set of CNC plans you will build from. You probably have some ideas for things you want to make with your CNC machine. This will help determine which machine you should get. There are two main considerations here: 1. How big are the parts that you intend to make? 2. What raw materials will the parts be made from?

Machine Size and Working Envelope

When thinking about what size machine you need, there is more to think about than just the overall dimensions of the machine. Of course the machine has to fit in your workshop(or in your living area, as some people do). So, ensure the overall dimensions will fit in your workspace. Consider the working envelope of the machine and if it will fit the largest parts you want to make, along with some additional buffer. You may need additional space allowances for holding your workpiece in place on the CNC router table. This could mean room for clamps, a vice, vacuum pods, or extra material around the edges for screws to hold down your workpiece.

Materials to be Machined

If you are only doing woodworking or machining plastics, then you do not need to rule out any of the machines. On the other hand, for machining harder materials like soft metals (aluminum, brass, copper) a stiffer, higher performance machine will work best. CNC routers aren’t ideal for milling harder metals like steel, although it can be done with certain machines at very low material removal rates (meaning, very time consuming). If your primary goal is to machine metals, you should consider looking at CNC milling machines rather than CNC routers.

Performance of the CNC Router

There is a wide range of performance across the various machines that can be built from plans. On the lower end of the spectrum, some machines would only be considered useful for learning about CNC or for light hobby use, while others can be used by small businesses to do production work. So how do you define performance of a cnc machine? It comes down to accuracy, precision, repeatability, speed, acceleration, and material removal rates. You could also add a discussion of finish quality, vibration, and stiffness, but those details will be saved for another article.

Accuracy refers to the difference between the dimensions of a machined part and the dimensions of the design (CAD model or drawings). Accuracy depends on the precision and repeatability of the machine.

Precision refers to the smallest distance that the machine can be commanded to move. For example, if a stepper motor can move 200 steps per revolution and it is driving a screw that will move a nut 10 mm per revolution, the precision would be calculated as 10 mm / 200 steps = 0.05 mm per step of the motor. So, the smallest move that the router could be commanded to make is 0.05 mm. Machines are typically designed with much greater precision than the final accuracy they achieve.

Repeatability can be thought of as the variance between dimensions for multiple copies of the same part. Due to factors such as machine flex, vibration, runout, and backlash, the dimensions of the machined parts will not be exactly the same every time and will not match the design perfectly. These factors are what cause the majority of error in machines.

Determine how tight of tolerances are needed for your intended work. For example, does the accuracy need to be within +/- 0.001” or +/- 0.01”? For high precision metal machining, it will likely be 0.001” or less. For a woodworking machine, an error of 1/32” (0.03125”) or even more may be acceptable.

Speed

Speeds are typically broken down to feed speeds and rapid speeds. Feed speed is how fast the tool is being driven (linear speed through the material, not rotational speed of the tool) while it is cutting material. Rapid speeds describe how fast the tool is moving as it is repositioned while not cutting. These are usually defined in inches per minute (IPM), mm/min, or mm/sec. Note that the rotational speed of the tool is defined in terms of revolutions per minute (RPM) or surface feet per minute (SFM).

Speed alone is not enough to determine a machine’s performance. Even if a machine can move the tool really fast in three dimensions, it may not be a high performance machine if it can only take very shallow passes and small stepovers at a time when cutting material.

Material Removal Rate (MRR)

MRR describes the amount of material that can be cut or milled from a piece of stock in a given amount of time. This concept is helpful in characterizing the performance of a machine. If a machine is very stiff and well damped from vibrations, it can take deeper cuts with larger stepovers, removing a lot of material in a short amount of time (high MRR). On the other hand, if the machine can only handle very shallow passes with small stepovers, then the MRR is very low and the job is going to take a long time.

Unfortunately MRR is not a published specification for most machines, but the concept is presented here to get you to think about it and prevent you from judging a machines performance based on published maximum speeds.

Acceleration

Acceleration becomes important when working with detailed or smaller parts and when doing three dimensional (3D) work. Every time the machine changes direction in an axis, the machine has to decelerate and then accelerate back up to the feed or rapid speed. If the machine can’t handle high acceleration rates, it will have to slow down a lot earlier before changing direction, and will take longer to get up to speed. This translates to taking a long time to complete a job.

To wrap up the performance discussion, it can be very hard to compare machines as there is no no standardized testing done by the designers and little information published about the machines true performance. The best way to evaluate this is to watch videos of the machines in action and see how deep of cuts are being taken, how wide of a cut or how many passes to cut through a given thickness of material. Also read reviews and comments from builders about machine strength and stiffness.

Skills and Tools Required

Another important consideration is the types of tools that will be required to build the machine and the skills that the builder should have.

Consider your existing skills, experience, workspace, and tool set. Are you willing to invest in new tools and learning new skills to complete your CNC router? Depending on the design, you may need certain skills like woodworking, metalworking, welding, soldering, and electronics. Assessing what your current resources are and what you are willing to invest in will be vital when choosing a machine to build.

When comparing the various machines, look at what materials the frames are made from. They are usually either wood, aluminum, or steel. If you have a woodworking shop already, you’ll have an easy time building any of the wood framed machines. To build the aluminum or metal machines you may need to buy a parts kit rather than making the parts yourself, or pay someone to have the components fabricated for you. Some metal framed machines have been designed to be mostly bolted together from commercially available parts, which can be accomplished with just hand tools.

One nice thing about building from plans is that you can always modify the machine to fit your needs. For example, you could build a welded steel base for a machine rather than use dimensional lumber or aluminum extrusions. That being said, any deviations from the plans can add a significant amount of time to the build since it requires you to come up with the design.

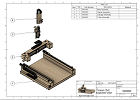

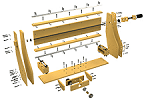

What to Expect in a Plans Package

There is quite a difference in what is included in the plans packages between all of the plans on the market. At one end of the spectrum, you will only receive a set of drawings. These drawings have all the information you need to build the machine, but may be intimidating for those who aren’t used to reading blueprints or technical drawings. At the other end of the spectrum, in addition to the mechanical drawings, there may be a Bill of Materials (BOM), discussion of design considerations, step by step instructions, pictures of the build process, links to suppliers for each part, and more. Some designs have builder forums that you’ll have access to and some have videos available that document the build. A few of the designs make the CAD files available for those that want to either modify the design or use them to have the parts machined by another CNC router.

So keep those things in mind when looking at the plans options. If you do better following a video, or having step by step instructions, this could help guide your decision. Of course you may not have that option if you’ve already ruled out certain plans from our prior evaluation points.

If you like shopping around to find the best deals, you may not care about having links to sources for each part.

If you want to use the plans as a rough guide or just as inspiration for your customized build, then you may want an option that offers CAD files of the machine.

Conclusion

In summary, the best CNC Router Plans for you is the one that you can afford to build and operate, and that can make the parts you want to make with the required performance. Using the information you’ve just learned, take a look at my list of 9 CNC Router Plans You Can Build Yourself and pick out your machine!

If you still have questions that weren’t addressed or have any comments for me, I would love to hear from you. Send a message to [email protected].